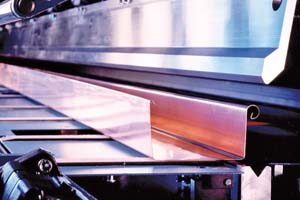

The new generation of pipe machines.

With the new generation of downpipe machines from AMB-WIBA, you can quickly, efficiently, and cost-effectively produce internally folded pipes in 5 different sizes with just one machine.

Also, the end processing of the pipes is carried out fully automatically.

Function:

The pipe machine automatically produces folded pipes in various lengths and in five different sizes. The expansion and retraction of the downpipes also work fully automatically, with the units being individually switched on or off. At the end, the pipes fall out of the machine ready for packaging.

Accessories:

- Discharge unit with the corresponding expanding and retracting heads for the respective diameters

- Embossing unit for a logo

- Changer for the respective pipe diameters

- Foil unit for applying protective films

Possible pipe diameters: ø 60mm - ø 150 mm

Compelling advantages:

- High flexibility through simple and quick conversion processes.

- Minimal labor costs due to simple single-person operation.

- Remote maintenance for quick and convenient issue resolution.

- Equipped with all safety precautions, including protective grilles, light curtains, etc.

- Rapid conversion to other diameters, as there is no fixed roller set in use.

- All motors, sensors, and settings can be managed via a display.

Key data at a glance:

- For the production of internally folded pipes in various sizes.

- Pipe diameter: 60 - 150 mm

- Pipe lengths: > 3 m - 10 m without end processing

- Pipe lengths: 3 m - 4 m including end processing

- Output: up to 18 m/min

- Sheet thickness: max. 0.8 mm

- Nominal power: 63 kW

- LxWxH: according to your configuration

- Total weight: approx. 18 tons (without coil)

These materials can be processed: Aluminum, steel, titanium zinc, zinc, pre-weathered titanium zinc, copper, steel coated

In case of need, this machine can be redesigned for a system for five welded pipes instead of the internal fold. Thus, you can produce welded pipes with our completely new pipe production system. There is no comparable system for pipe production on the market; simply inquire for more information.

Also, ask about our pipe expanding and pipe drawing systems, which can be operated independently of your existing machines!

Contact us today for a quote! sales / AMB-WIBA Maschinenbau GmbH

Suitable decoiler systems: 5T-700 Decoiler or our proven Pallet Decoiler