Gutter Machines – Precision and Efficiency for Professional Gutter Manufacturing

Advanced Machines for Gutter Production

Maximize the efficiency of your production processes with state-of-the-art gutter machines from WIBA, specifically designed for the precise and reliable manufacturing of various gutter profiles. These machines combine innovative technologies with robust design to meet the high demands of both industrial and artisanal applications.

Benefits of Gutter Machines:

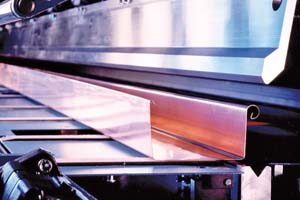

- High Production Speed: These machines enable rapid and continuous production of gutters from a variety of materials, including aluminum, copper, galvanized steel, and more. The high throughput speed is ideal for mass production where quality and efficiency are paramount.

- Modularity and Flexibility: Gutter machines feature modular designs that allow for easy adjustment and expansion of the production line. Whether you need half-round, box-style, or specialized profiles, the machines can be flexibly configured to produce a wide range of profiles.

- Precision Roll Forming Technology: With advanced roll formers and roller sets, these machines ensure accurate and consistent shaping that meets the high standards of the modern construction industry. This results in precise and durable gutters that comply with industry’s stringent standards.

- Integrated Automation: Automatic cutting, punching, and bending units are seamlessly integrated into the production line, making the manufacturing process more efficient and less labor-intensive. This automation reduces errors, minimizes waste, and enhances overall productivity.

- Maintenance-Friendly and User-Friendly: The machines are designed to be not only robust and durable but also easy to maintain. Intuitive user interfaces and easy access to machine components simplify maintenance and reduce downtime. Additionally, user-friendly control systems provide simple operation and quick adjustments, increasing flexibility in production.

Technological Highlights:

- Servo-Controlled Systems: These machines feature highly precise servo controls that allow for exact adjustment of rollers and profiles, leading to consistent and high-quality results. This is particularly important for manufacturing gutters that must meet specific requirements and standards.

- Material Versatility and Adaptability: Gutter machines are designed to handle a broad range of materials, including both light and heavy metals. This allows manufacturers to tailor their products to varying customer needs and serve different market segments.

- Energy Efficiency: By employing energy-efficient drive systems, these machines help reduce energy consumption and operational costs, which is beneficial both economically and environmentally.

Investing in the Future of Your Gutter Production

Utilizing modern gutter machines enables you to optimize your production processes, enhance product quality, and increase your competitiveness. These machines represent a long-term investment in the future of your business, helping you meet the growing demand for high-quality gutters. Contact us to find the best solution for your specific requirements and achieve your production goals.

Contact us today: sales / AMB-WIBA Maschinenbau GmbH

For more information, visit: Gutter Machine