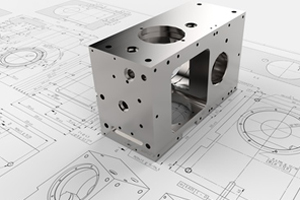

High efficiency through optimally customized machines.

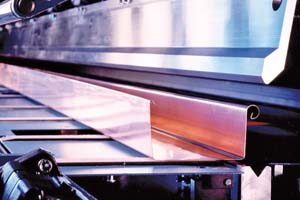

We design and manufacture special machines for your specific application, whether components need to be processed, punched, drilled, bent or assembled.

Feeding the raw material into the machine:

- Raw materials in bulk form are put into their correct place by the sorting machine and can thus be fed into the system at the right moment.

- • When manufacturing sheet metal coil, the sheet metal strip is fed step by step into the machine with the help of cycle feed units. Through consecutive process steps, a different process is performed on the sheet metal strip in each cycle. By doing this, stamped, punched and perforated parts can be manufacturedsee snow guard machines for further machines watch: RINNENAUTOMAT AMB-WIBA 6000

These machines are used for:

- Identical, repeated process steps.

- A number of consecutive process steps.

- Precise positioning work.

- Turning work.

Examples of machines:

- Milling of wooden wheels for toys.

- Milling of tenon joints for wooden ladder rungs.

- Bending of retaining clips.

- Joining of parts.

Key benefits:

- Cycle-based production.

- Consistent quality.

- High efficiency.

- Minimal labor costs.