Machine for the Finishing of Drainpipes.

The self-contained machine for inserting and expanding the ends of drainpipes or downspouts performs all work steps automatically, allowing the pipe to be taken out fully processed at the end.

Function:

If the machine is operated autonomously without our pipe machine, the pipes must be manually placed on a conveyor belt. The machine then automatically positions the pipes and conveys them through the individual assemblies where the ends of the pipes are either inserted, expanded, or both. At the end, the finished pipes are conveyed out of the machine and can be packaged.

Accessories:

- Expanding and Inserting heads for the respective diameters

Possible Pipe Diameters: ø 60mm, ø 80mm, ø 100mm, ø 120mm, ø 150mm

Compelling Advantages:

- High flexibility as all standard diameters can be processed automatically.

- Easy loading of the system by placing your produced pipes on a conveyor belt (the machine handles the rest).

- No cumbersome turning of the pipes is necessary to process the ends.

- All work steps are manageable via a display.

Key Data at a Glance:

- Pipe Diameters: 60 - 150 mm

- Pipe Lengths: 2.5 m - 4 m including end processing

- Output: according to the cycle speed

- Nominal Power: 16 kW

- LxWxH: according to your configuration

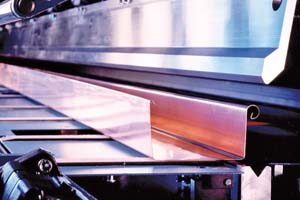

Materials that can be processed: Aluminum, Steel, Titanium Zinc, Zinc, Pre-weathered Titanium Zinc, Copper, Steel coated

This machine can be operated autonomously with your system or automatically connected so that loading also works automatically.

Ask for more information; we are happy to inform you and can also provide an online video.

Suitable Uncoiling Systems: 5T-700 Uncoiler or our proven Pallet Uncoiler