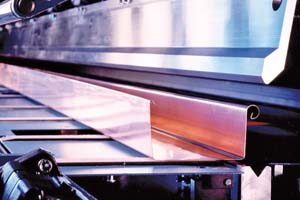

Over 30 years experience in roll forming.

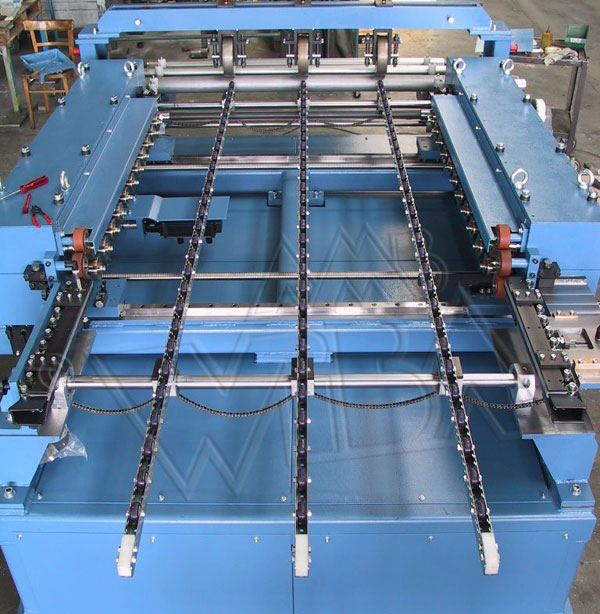

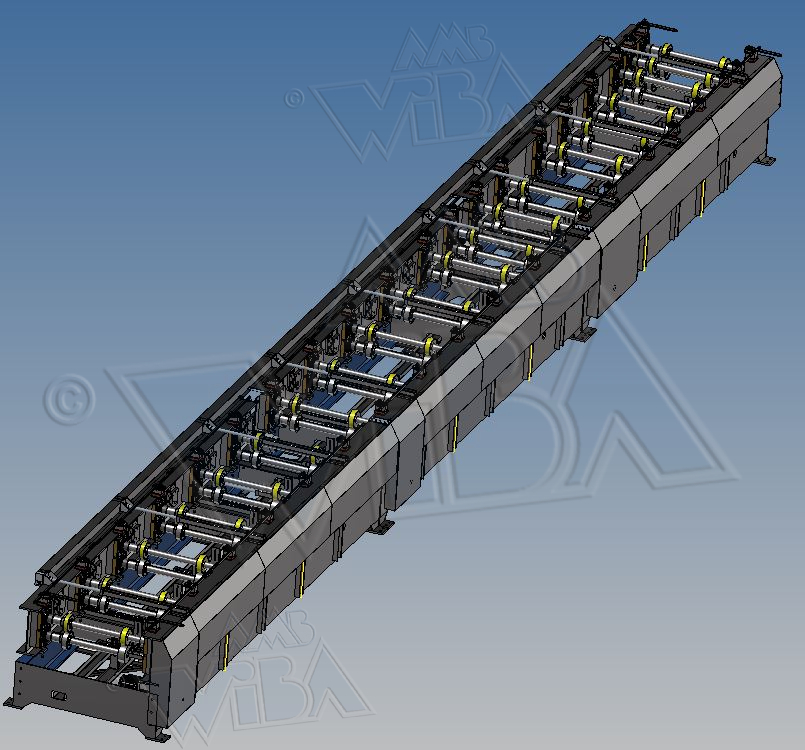

To meet the requirements of the forming work, we build roll formers with just a few roll stands, but also systems with up to 40 roll stands. The diameter of rolls can also vary from ø 40 mm to ø 500 mm.

The system settings can be controlled manually or fully automatically by a servo motor depending on the degree of automation. All units e.g. scissor, punches, can be fitted either fixed to the machine or overhanging. A subsequent stack-off and packing unit makes the process of handling the finished sheets easier.

From sheet decoiler to stack-off and packing, we offer a complete system under one roof. We configure our roll formers to suit your needs.

Accessories / options:

- Decoiler

- Punching tool for subsequent folding and perforating.

- Straightening unit for eliminating stresses and unevenness in the metal sheets.

- Profile or standard cutting unit.

- Modules for metal blank processing

- Bending systems (eaves and ridge)

- Spray lubrication system

- Sealing strip adhesive system

- Labeling system for barcode recognition

- Stack-off system for sheets of up to 35 m including packing unit.

- etc.

Applications of our roll formers:

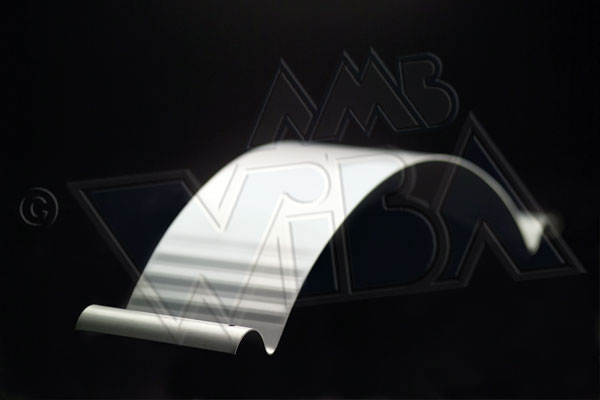

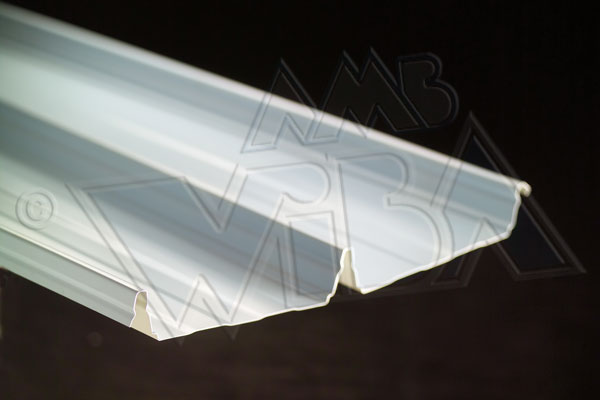

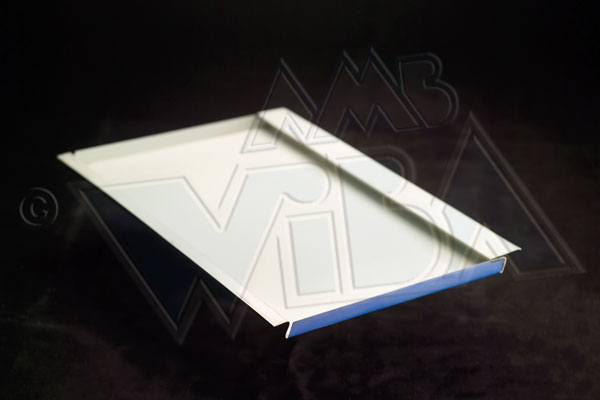

- For roof profiles e.g. trapezoidal sheets, corrugated sheets usw.

- For wall profiles / facade profiles

- For substructures of all types e.g. retaining strips for roof and wall profiles

- For cable trays

- For roller shutter boxes

- Door and window profiles

- Double-head roll former for door panels or sandwich panels e.g. for refrigerated van bodies, cold stores, fire doors and walls

- Other profiles, manufactured by roll forming

Industry sectors using our roll formers:

- Automotive industry

- Window industry

- Construction industry

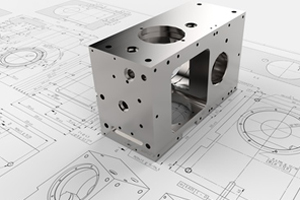

- Mechanical engineering

- Electronics industry

- Roof drainage

- Facade engineering

Key benefits:

Years of experience in the field of roll forming enable us to design and manufacture robust roll formers which deliver top quality profiles. The flexible configuration of the systems means that they can perform many process steps automatically during, before or after roll forming. This saves an enormous amount of time, since no afterline and thus no laborious turning and flipping is required.

Compatible decoilers: 5T-700 decoileroder unser bewährter pallet decoiler