Simple units that fulfill their purpose optimally!

These units are used in sheet metal strip processing and facilitate certain tasks.

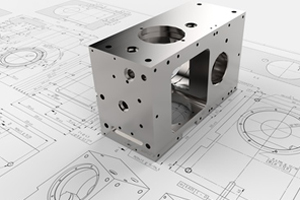

Over the years, we have manufactured many roll formers and special machines for the sheet metal processing industry. Individual components from the overall systems can be combined as desired.

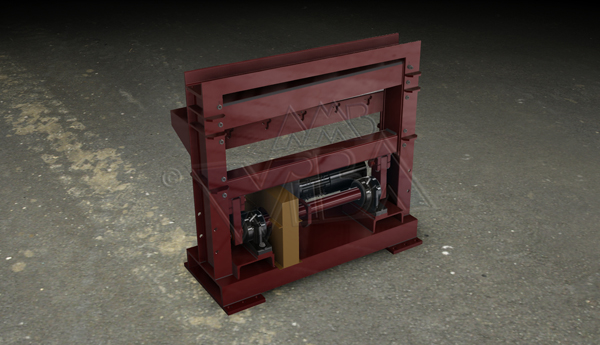

Eccentric Shear

The shear operates on the principle of a guillotine shear and is driven by a spur gear motor via an eccentric shaft. The shear allows for precise and fast cutting through the sheet metal without waste.

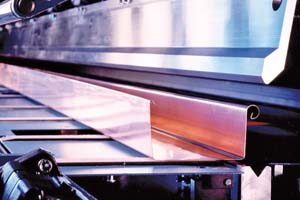

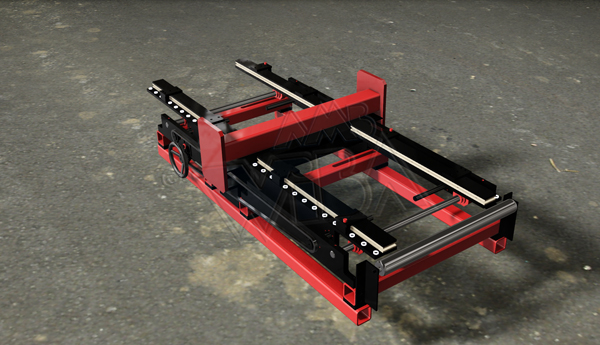

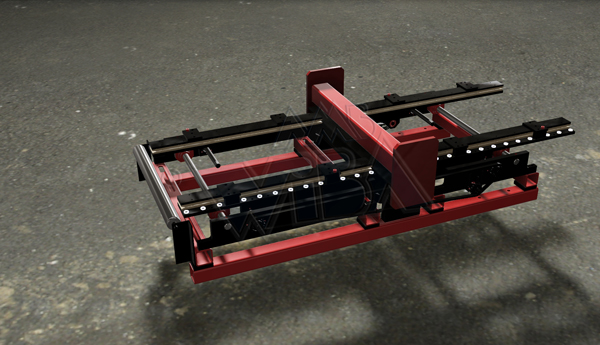

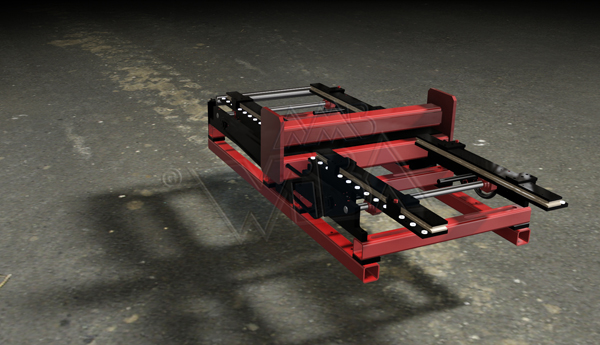

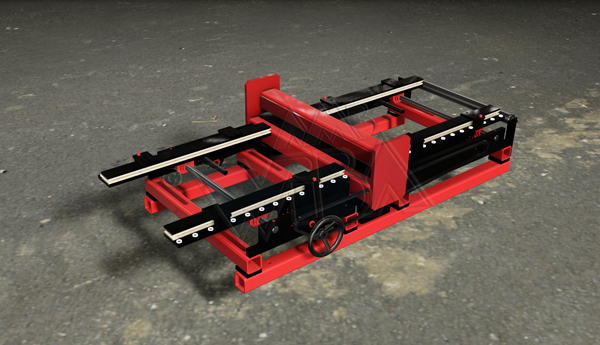

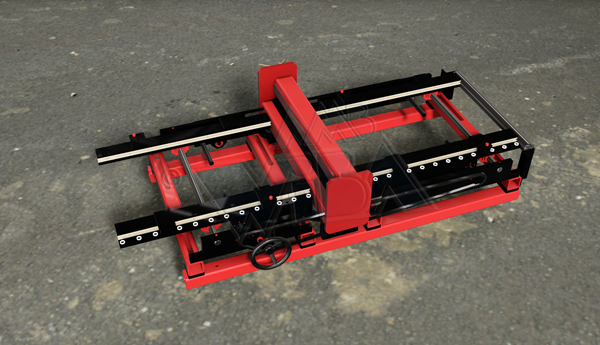

Sheet Metal Guide

In principle, we manufacture sheet metal guides in all conceivable designs with manual or motorized side adjustment.

The side-adjustable sheet metal guide shown in the photo is used to align the sheet metal for a parallel entry into the subsequent machine, such as a punch, shear, or roll forming machine. As an option, we offer an integrated cutting wheel for cross-cutting the sheet metal with this variant. The cutting process can be performed manually or pneumatically. The guides can be adjusted separately on the left and right using a hand crank.

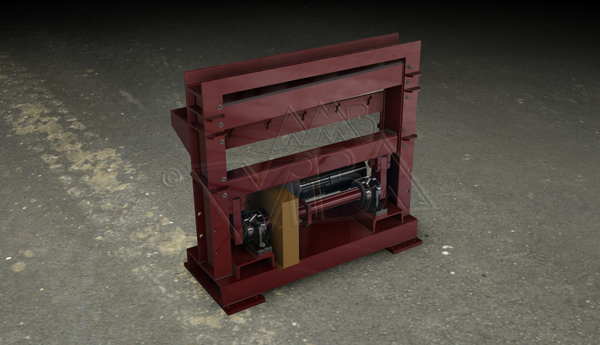

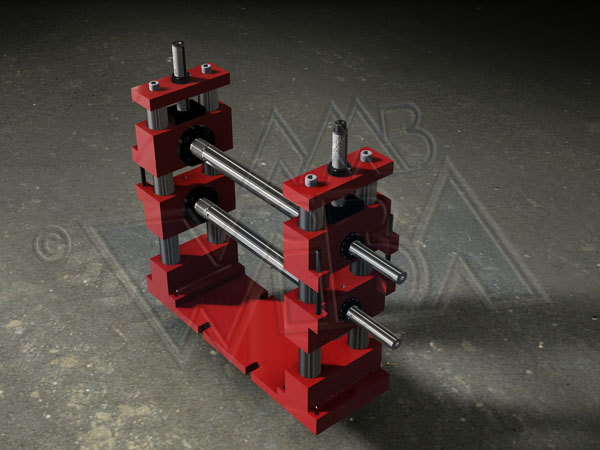

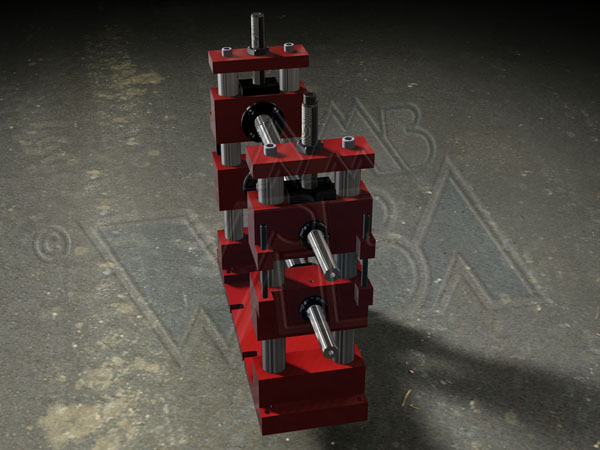

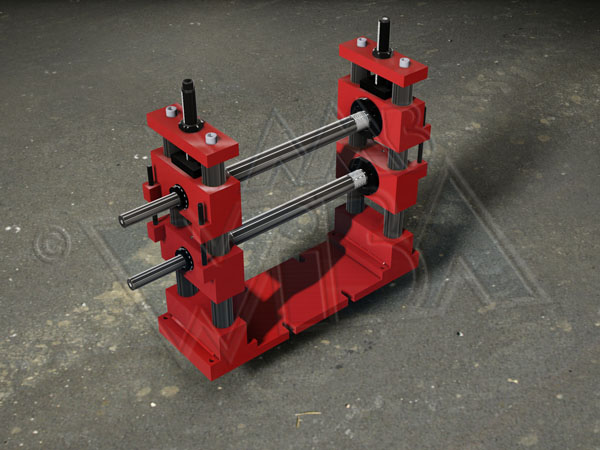

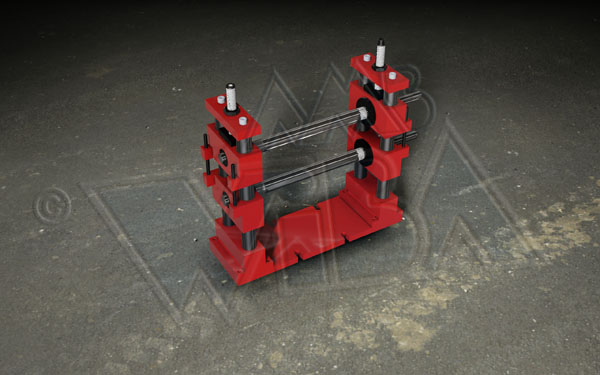

Roller Stand

Our standard roller stand is ideal for quickly and easily mounting shape rollers or rubberized drive rollers on a shaft. The roller stand is characterized by the ability to adjust both the upper and lower shafts in height using a threaded spindle. Continuous lowering is thus possible. A keyway on the shaft stub allows for the mounting of a gear or pulley.

Roller Conveyor

We manufacture roller conveyors in various designs. In addition to different heights, widths, and lengths, we produce powered and non-powered versions with side stops or inclined rollers.