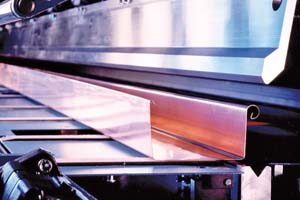

A simple system for a trouble-free process.

Through a robust design, the hydraulic ladder press enables the rungs to be precisely connected to side rails of up to 6 meters long.

With just a few hand levers, the machine can be adjusted to different ladder widths. Converting the machine from angled to parallel rails is also really easy. The machine can be individually tailored to your requirements, depending on how your rungs and rails are prefabricated.

Details:

To press a ladder, the rails and rungs must be inserted into the fixtures provided. The fixtures for the rungs can be adjusted slightly. To manufacture angled ladders, an angle fixture is swung into the machine. Using adjustable roller switches, the automatic switchover point of the press width must be set. The machine now automatically presses until the switch is activated and then the machine returns to its original position.

Key benefits:

- Semi-automatic for easy operation.

- Angled and parallel ladders can be pressed

- Lengths of 1 - 6 m can be produced.

- Twisting of the ladder is prevented by the precisely manufactured guides and parts.

Key data at a glance:

- Connected wattage: 4 kW

- Press force: approx. 37.5 tons at 100 bar

- Max. ladder length: 6 m

- Weight: 4400 kg

- Size LxWxH: 6.2 m x 2.1 m x 1.6

Used with: Machine for milling tenon joints.