Very high performance with high flexibility

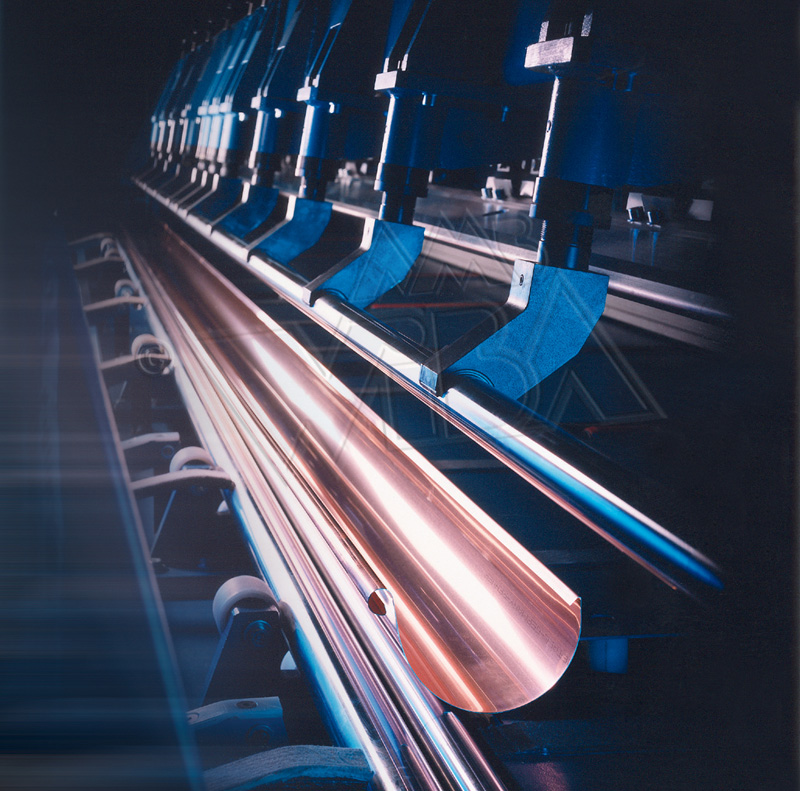

Our gutter machine has been constantly developed for over 30 years and is thus an absolute trendsetter in industry circles. This precision-designed special machine is based on two basic configuration types and is tailored exactly to customer requirements.

Function:

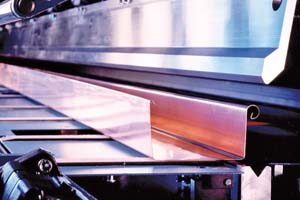

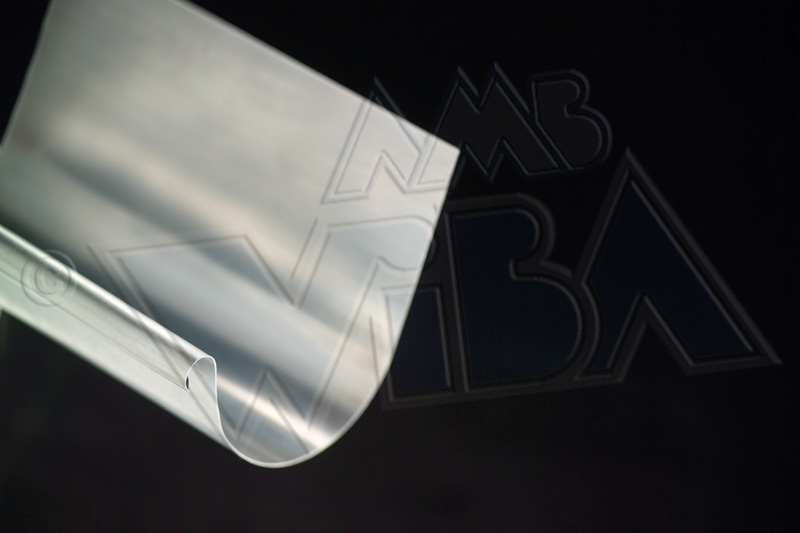

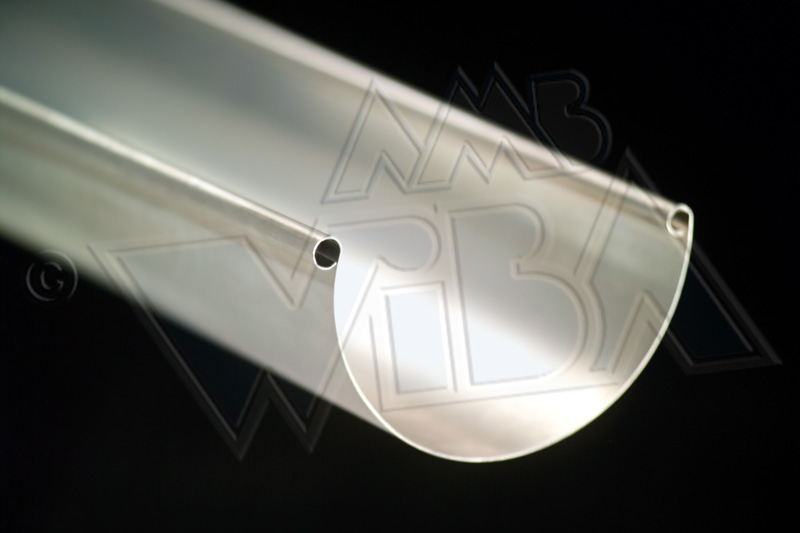

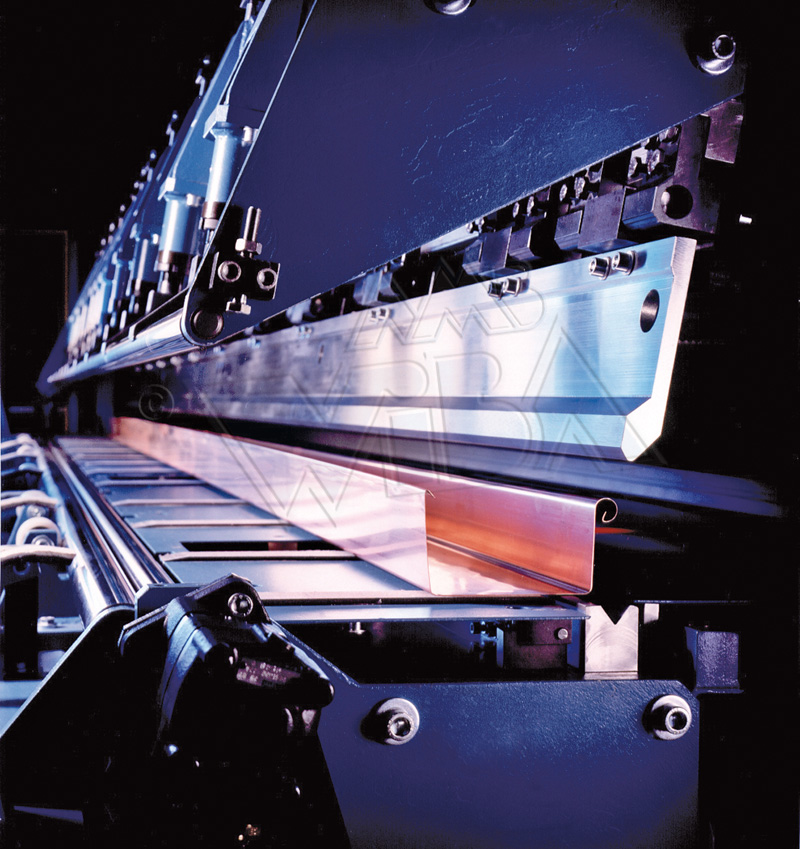

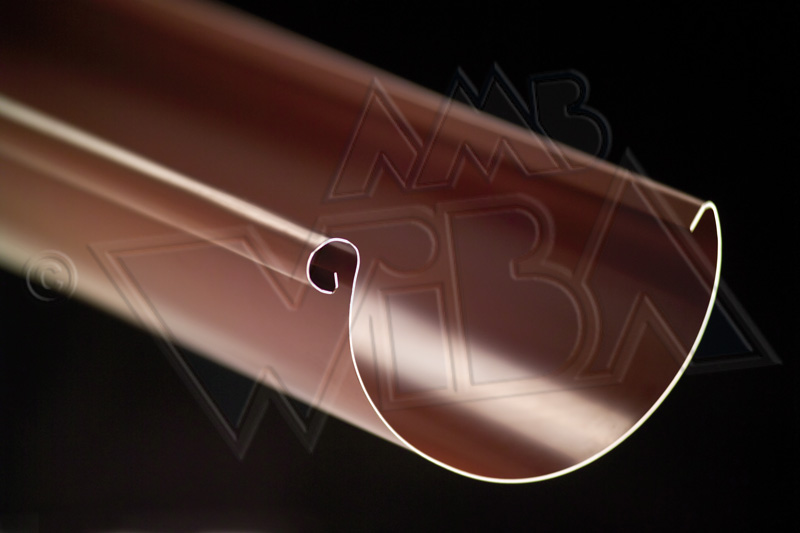

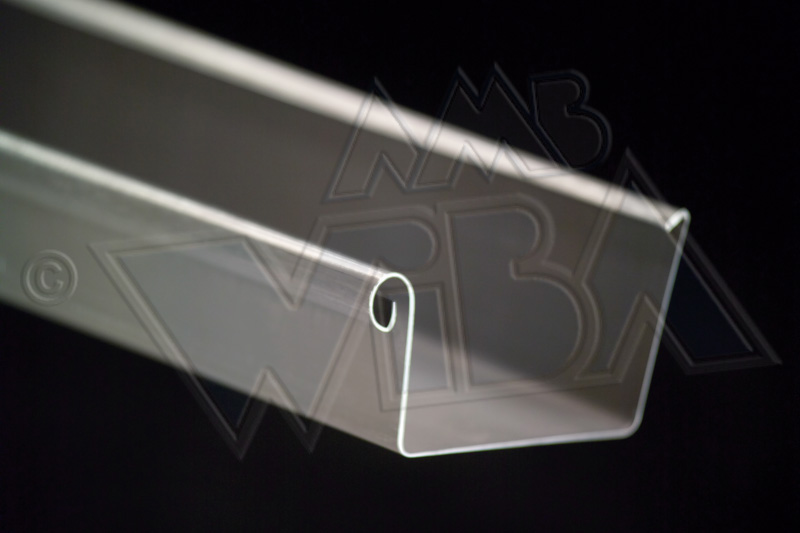

The gutter machine fully automatically produces half round gutters and rectangular gutters in different lengths and sizes. Alongside the standard gutter profiles, custom shapes can also be produced depending on the roll set. A visualized touchscreen display allows for easy operation of the machine. The entered parameters can be saved separately for each gutter profile, enabling quick retooling. Selected from the display, all sheet metal side guides and roll sets are set to the correct positions according to the standard gutter size (200, 250, 280, 333, 400, 500). Since all materials behave differently in the manufacturing process, material-specific values can also be saved in the program.

Basic design:

- Fully automatic gutter machine

All sheet metal guides and spindle lifting gears are driven by motors with travel measuring systems. During a product change, e.g. standard size 500 mm to 250 mm, all drives are set automatically to the values stored in the program.

- Semi-automatic gutter machine

The sheet metal guides and spinle lifting gears must be set manually by a crank handle.

Both basic designs are available in two versions:

- For half round gutters only

- For half round gutters, rectangular gutters and edge profiles

We also offer a number of accessories and tools for special requirements.

Accessories:

- Labeling system for barcode scanners

- Lubrication system

- Stamping unit

- Punching unit

- Workbench for working on metal blanks

- Roll sets for custom shapes or different bead diameters (ø16, ø18, ø20, ø22)

- Revolver for automatic changing of up to 4 roll sets

- Automatic unloading system / handling system

- Straightening unit for metal sheets

- Foil unit for applying foil protection

Key benefits

- High flexibility through quick, easy retooling. (the machine can be converted from nominal size 333 to 250 in approx. 5 min).

- During production of 2 m gutters, 2 strips can be manufactured at the same time.

- Roll sets can also be added later at minimal cost to further extend your range of products.

- Large production volumes and extremely short retooling times.

- Negligible to no stock keeping of finished gutters.

- Minimal labor costs through simple one-man operation.

- Remote maintenance for quick and easy troubleshooting.

- Modern recipe management by use of a touchscreen display.

- Equipped with all safety devices incl. safety guards, light curtains, etc.

Key data at a glance

- Sheet width: 200-500 mm (-750)

- Sheet thickness: 0,4 – 0,9 mm

- Gutter length: 2 – 6 m

- Output: up to 1800m/h (for 6 m round gutter)

- Wattage:approx. 16 kW

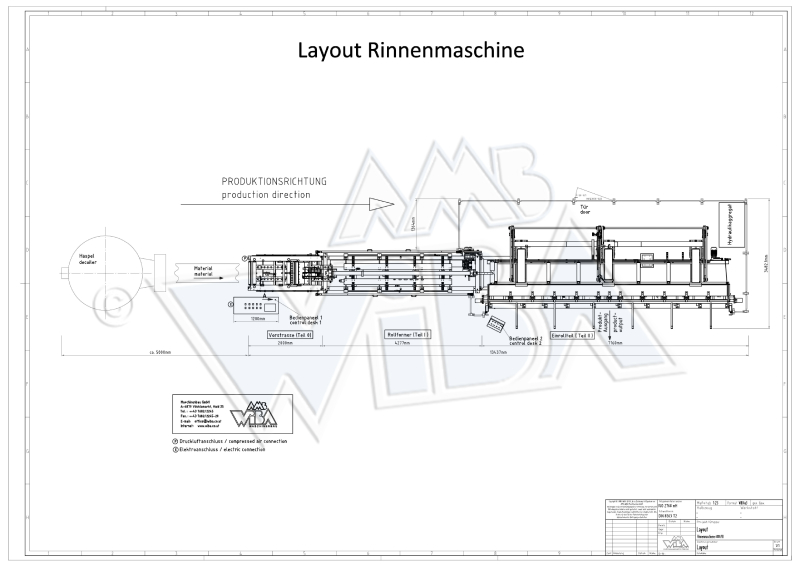

- LxWxH: 13.2m x 3m x 2.4m

- Weight approx. 12 tons (without decoiler)

Possible guter types: K-Style, Berlin gutter, half round gutter, rectangular gutter, roof gutter, edge gutter, French drain, Dutch gutter

These materials can be processed: Aluminium, steel, titanium zinc, zinc, pre-weathered titanium zinc, Uginox, Ugitop, copper, coated steel

Compatible decoilers: 5T-700 decoiler decoiler or our tried and trusted pallet decoiler