Easy to use, easy to handle.

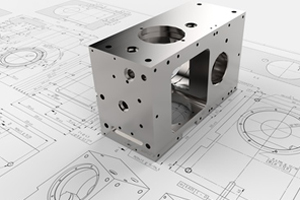

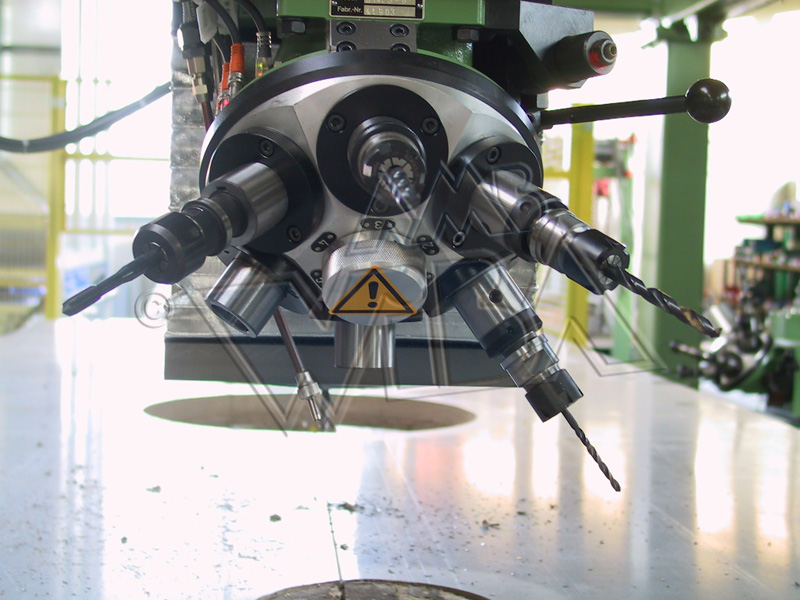

The machine is used for the fully automatic processing of different elements on all sides, providing these elements with all the necessary holes, threaded holes, countersinking and milling contours.

The individual data and parameters needed for each element is saved in the machine system and can be accessed and modified at any time.

Process description:

The element to be processed is taken from the store and brought to the final processing station via the roller conveyor system, after which we clamp the element and process it as specified in the program. After processing, the element is conveyed from the danger zone to the picking area. Whether rhombus-shaped, round, square, semi-circular, the machine mills each contour precisely so that no reworking is needed and that e.g. spy holes, door handles and locking mechanisms can be added according to the application. The extraction system which is connected to the gantry milling machine starts up automatically to immediately remove swarf and dust.

Applications:

- Cutting out complex contours of all types for e.g. spy holes, door handles

- Fabricating holes and threads for hinges on the sides of elements.

- Fabricating door lock cut-outs as well as the relevant holes.

- Ideal for sandwich panels, insulation panels, doors, fire doors, wall elements, facade elements, windows, etc.

Relevant sectors for our gantry milling machines:

- Automotive industry

- Window industry

- Construction industry

- Mechanical engineering

- Facade engineering

- Door and gate industry

Key benefits:

- Multiple processing cycles can be completed on one setting in just a few seconds.

- Precise fabrication eliminates the need for cost-intensive reworking.

- No turning and flipping on difficult elements.

- Minimal labor costs due to easy one-man operation.

- Automatic tool change allows fabrication of many different holes and milling.

- Modern recipe management by use of a touchscreen display.

The machine is individually tailored to your products.