Simple innovations, proven many times over.

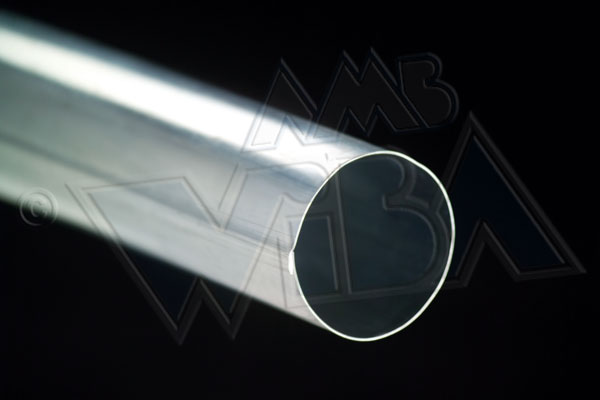

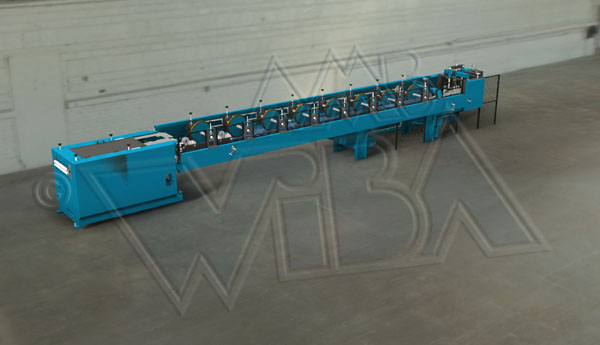

The downpipe machines have also been developed over many years. The downpipe machines from AMB-WIBA are used to produce low-cost crimped pipes quickly and efficiently in different sizes.

Function:

The pipe machine fully automatically produces crimped pipes in different lengths and sizes. The pipes are tapered at the end so that they can be joined together. An automatically controlled ejector unit with tray slide connected to the machine allows the finished pipes to be removed outside of the production cycle.

Accessories:

- Labelling system for barcode scanners

- Lubrication system

- Stamping unit

- Workbench for working on metal blanks

- Changeable rolls for different pipe diameters

- Foil unit for applying foil protection

- Pipe expander

- Pipe fitting machine

- Automatic unloading system / handling system

Possible pipe diameters: ø 60mm - ø 150 mm

key benefits:

- High flexibility through quick, easy retooling.

- Minimal labor costs through easy one-man operation.

- Remote maintenance for quick and easy troubleshooting.

- Equipped with all safety devices incl. safety guards, light curtains, etc

- Quick conversion for different diameters, since no fixed roll set is in use.

Key data at a glance:

- For the manufacture of crimped pipes on different sizes.

- Pipe diameter: 60 - 150 mm

- Pipe lengths: > 2 m - 10 m

- Output: to 25 m/min

- Sheet thickness: max. 0.8 mm

- Wattage: 9,5 kW

- LxWxH: 15.6m x 1.6m x 1.95m (without decoiler)

- Est. weight: approx. 4 tons (without decoiler)

These materials can be prodessed: Aluminium, steel, titanium zinc, zinc, pre-weathered titanium zinc, Uginox, Ugitop, copper, coated steel

Ask about our pipe expander and pipe fitting machine!

Compatible decoilers: 5T-700 decoileror our tried and trusted pallet decoiler