For those who want to offer their customers higher quality.

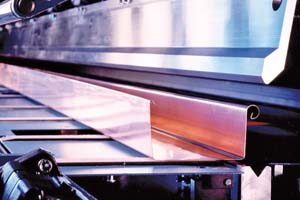

Our 7-roll strip feeder straightening machine with an integrated shear is ideal for counteracting the natural coil curvature after unwinding.

Function:

Through a sophisticated belt system, 4 out of 7 straightening rollers are driven without slipping. Furthermore, a very fine and precise straightening gap adjustment is possible using a handwheel and bevel gear. An incremental rotary encoder in combination with a "flying" shear allows trimming the sheet metal without interrupting the feed. Approximately 0.5 m before the cut, the belt speed is slightly reduced to ensure an exact length of the cut sheet metal. 1 sec. after the cut, the speed is increased back to the set speed. Rubberized feed rollers provide the necessary forward movement of the sheet in the system.

These assemblies are integrated into the feed straightening machine:

- Straightening device

- Length measurement

- Feed unit

- "Flying" shear

- Extraction unit

- Sheet metal side guides

Compelling advantages:

- Precise straightening gap control via eccentric and fine adjustment via spindle gear.

- No hydraulics

- Easy accessibility for cleaning

- Straightening rollers are made of tool steel with a hardness of 60 HRc and strength of 900-1300 N/mm²

Key data at a glance:

- Feed speed: 55 m/min

- Minimum sheet length: 1000 mm

- Material yield strength: 400 N/mm²

- Size LxWxH (mm): 2200x1200x1250

- Tension rollers (mm): ø121

- Straightening rollers (mm): ø60

- Sheet thickness: 0.4-1 mm

- Sheet width: 150-600 mm

- Number of straightening rollers: 7 – 4 x driven, 3 x idler

- Material: Coated/natural steel and aluminum sheets, VA2

- Quantity input on display

- Length input on display

Accessories:

- Labeling system for barcode scanner

- Foil unit for applying a protective film

This system is ideal for sheet metal workers, roofers, and other trades that want to deliver better sheet metal plates to their customers.

Suitable decoiling systems: 5T-700 Decoiler or our proven Pallet Decoiler

.JPG)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)