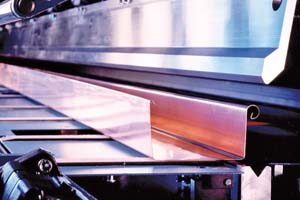

Simple system with high precision.

The hydraulic punch for sheets and plastic allows for quick and easy punching of round, square, rectangular, or special shapes.

The tool units consist of a die holder plate, die, punch guide plate, and punch. Since these units are already pre-assembled, tool changes can be done within 3 minutes.

Areas of application:

- Creating breakthroughs in motor fan hoods.

- Punching in window and door frames, cable guides.

- etc.

Compelling advantages:

- Many different contours and shapes are possible.

- Compact design.

- Footswitch for easy operation.

- Low effort in setup processes.

- Due to the robust construction, a reach of up to approx. 300 mm is possible.

- Wear-resistant tool holder with a simple locking system.

- Depth stop

- Low-noise compact hydraulic unit.

- Protective covers on all sides.

- All tools are made of high-quality tool steel and are hardened.

Key data at a glance:

- Space requirement: approx. 1000 mm in ø

- Weight: approx. 205 kg

- Punching force: 130,000 N at 600 bar

- Punchable materials: Aluminum, steel

- 2 mm steel sheet (aB max = 400 N/mm²) at 110 mm cutting contour length