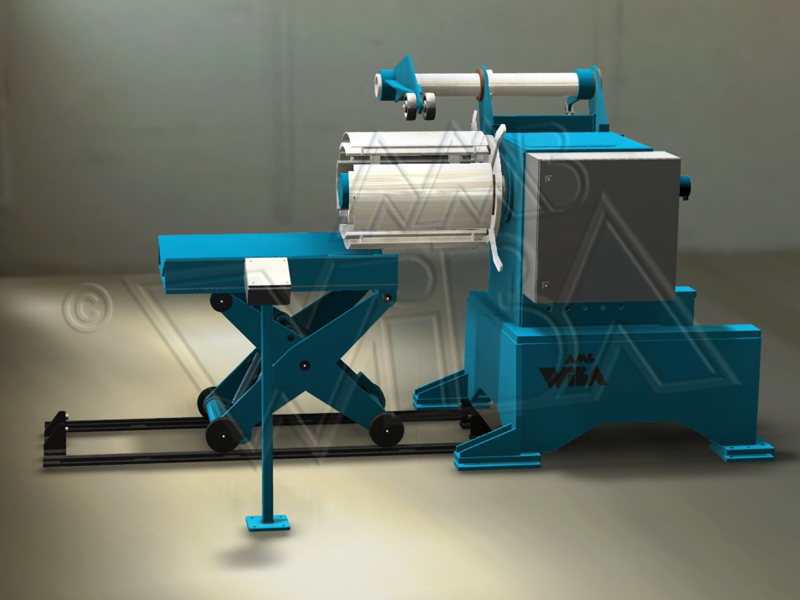

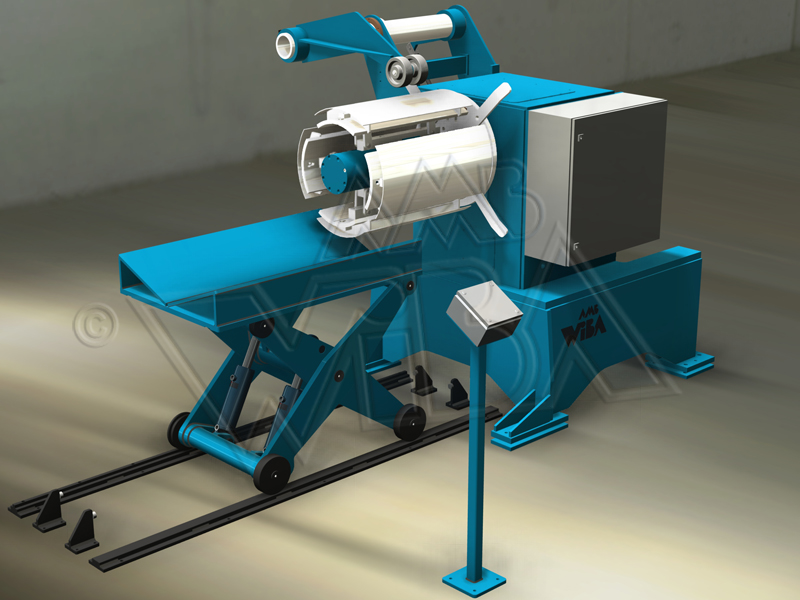

Easy loading of the decoiler system with the help of a scissor lift table.

The system is used to decoil sheet metal coils in conjunction with a sheet metalworking machine. The Sheet metal coils of up to 5 tons can be positioned directly with the help of the scissor lift table and hydraulically clamped.

The speed is controlled via a sensor or loop control. This adjusts the strip speed precisely and dynamically to match the production speed. A pneumatically-actuated pressure arm enables the coil to be opened safely. The sheet metal can then be uncoiled in any direction and fed to the following sheet metalworking machine.

Key benefits:

- Easy clamping of the coils by hydraulic expansion of the spindle.

- Easy loading of the system via a scissor lift table

- High flexibility through quick, easy retooling

- The pressure arm enables the coil to be opened safely.

- Electrical braking system to safely stop the turning coil.

- Equipped with all safety devices (e.g. emergency stop functions for interlinked machines, safety guards)

Key data at a glance:

- Connected wattage: 3kW

- Strip speed: 41 m/min

- Max. coil weight: 5 tons

- Max. coil width: 700 mm

- Actuator type: Loop or sensor control

- Size incl. lift table LxWxH: 4 m x 1.7 m x 2.1 m

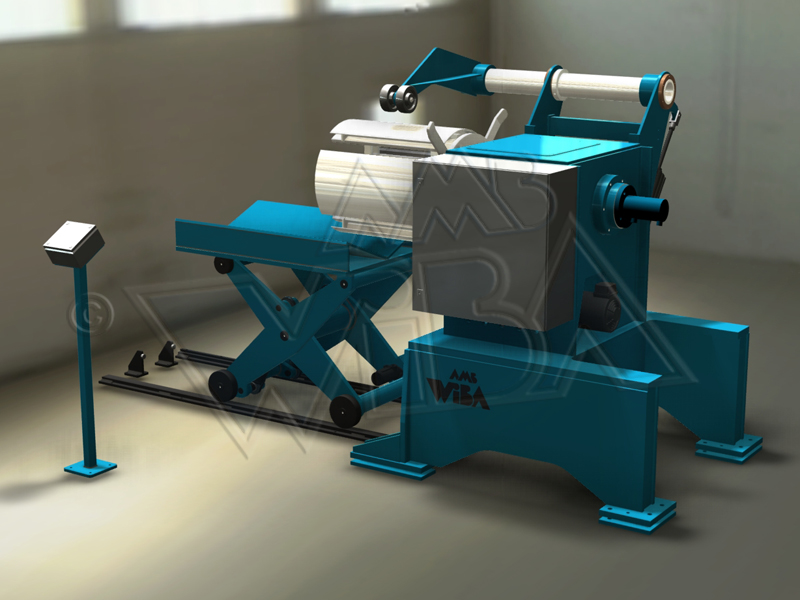

New: Decoiler with Rotating Turret!

Our latest innovation: The decoiler with a rotating turret offers even more flexible and efficient coil feeding. Thanks to the motorized rotation function, the coil can be unwound in the optimal position, making handling easier and improving production processes.

Advantages of the rotating turret:

- Enables flexible coil feeding regardless of the unwinding direction.

- Motorized drive ensures precise rotational movements.

- Reduces setup times and optimizes material flow.

Experience the benefits of our decoiler with a rotating turret in action: