GUTTER AUTOMATION SYSTEM AMB-WIBA 6000

Technical Description:

The newly developed AMB-WIBA 6000 gutter automation system uses the proven cross-forming technology for the production of gutters. This technology ensures gutters are produced with minimal tolerances across their entire length. The 6000 model is the first to combine cross-forming with automation. The fully automatic system allows for continuous production with single-person operation. During the design of the entire system, careful attention was given to avoid friction surfaces that could damage the material surface.

Apart from the interchangeable roller consoles, there are no parts required for the changeover from one dimension to another, keeping the changeover time very short (approximately 5 minutes). The bending tool for box gutters can also be automatically engaged. This new process allows all types of sheets (galvanized steel sheet, copper, aluminum, zinc, and plastic-coated materials) to be processed into high-quality gutters.

Components:

-

Decoiler: The sheet metal strip is unwound from the coil using an electrically operated decoiler controlled by strip tension via limit switches (maximum coil weight 3 tons).

-

Cut-to-Length Section: A pre-programmable, impulse-controlled length measuring device controls a flying shear that cuts the sheet metal strip to the required length without interrupting the feed.

-

Roll Forming Section for Hook and Bead: In this section, the bead and hook are formed using sets of forming rollers. The system is designed so that the forming roller sets can be changed within a few minutes, allowing for quick product changeovers. A light curtain on both sides of the roll former ensures safety at potential hazard points.

-

Forming Roller Sets for Special Products: Using appropriate forming roller sets, various other products such as special gutters, beaded sheets, neck sheets, eave sheets, etc., can be produced in any length.

-

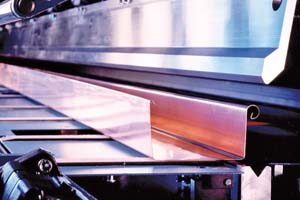

Rolling Section: The sheet metal strip with the bead and hook, but otherwise flat, automatically enters the three-roll bending machine. Here, the gutter is rounded. This rounding is also done crosswise, ensuring a uniform roundness of the entire gutter. The radius in the rounding machine is infinitely adjustable to accommodate all hardness grades and thickness variations of the material, an advantage not available with traditional roll formers for gutter production. Additionally, a bending tool can be automatically engaged to produce box gutters, quarter-round gutters, or other bent parts.

-

Control Panel: A control panel integrated into the base unit allows for manual operation of each individual function or automatic cycle operation. All control elements are arranged in a clear, ergonomic manner. The gutter machine is controlled via a Siemens S7 TIA PLC, which is operated through a visualized touchscreen display. A USB interface allows for saving/loading created programs to/from a USB stick or PC. Templates for various gutter productions can be saved and/or copied, enabling new recipes to be set up quickly. Depending on the version, all drives automatically adjust to the parameters stored in the recipe.

-

Hydraulic System: A fully automatic oil-hydraulic system (160 bar operating pressure) supplies all hydraulic cylinders required for automatic production.

-

Special Equipment:

- Labeling system for barcode scanner

- Lubrication system

- Inkjet printer for marking the gutters

- Embossing unit

- Punching unit

- Support table for sheet processing

- Roller sets for special shapes or different bead diameters (ø16, ø18, ø20, ø22)

- Turret for automatic changeover of up to 4 roller sets

- Automatic stacking system/handling system

- Sheet straightening unit

- Foil unit for applying a protective film

- Etc.

Technical Data:

- Sheet Width: 200-500 mm

- Sheet Thickness: 0.6-0.9 mm

- Gutter Length: 2-6 m freely selectable (up to 3 m also possible in double-strip operation)

- Output: up to 1800 m/h (for 6 m round gutter)

- Rated Current: 35 A

- Maximum Fuse Protection: 63 A gG

- Maximum Short-Circuit Current: <10 kA

- Nominal Voltage: 400/230 VAC + N + PE

- Dimensions (LxWxH): 14 m x 3 m x 2.4 m (without decoiler)

- Weight: approx. 12 tons (without decoiler)

for further information please watch: Dachrinnenmaschine